Connect production, maintenance, and costing - automatically.

Coordinating production, maintenance, and costing across multiple lines or plants is a constant balancing act. Most manufacturers still rely on disconnected systems for planning, maintenance tracking, and cost control - leading to downtime, inefficiency, and margin loss.

Connect Production, Maintenance & Costing

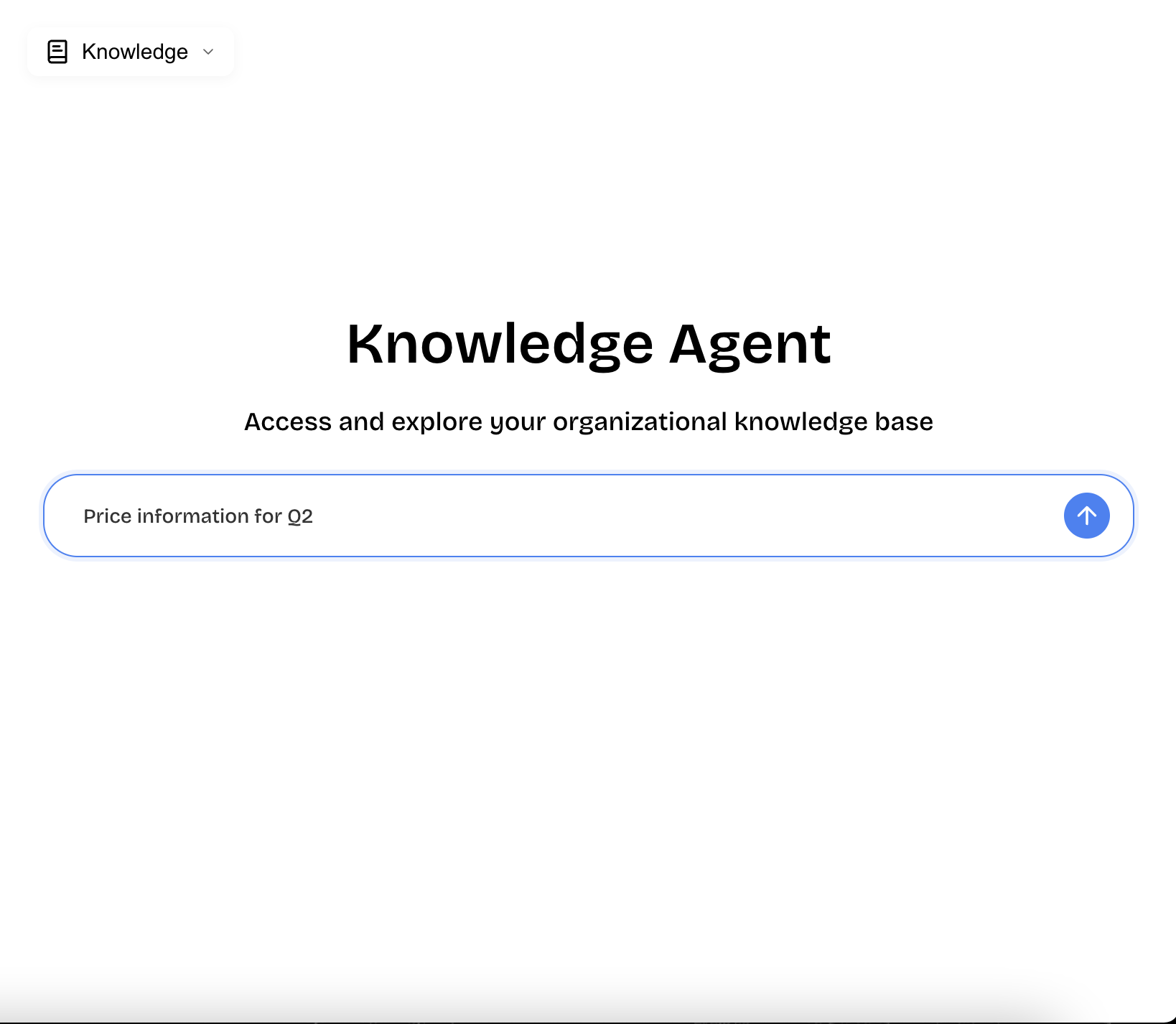

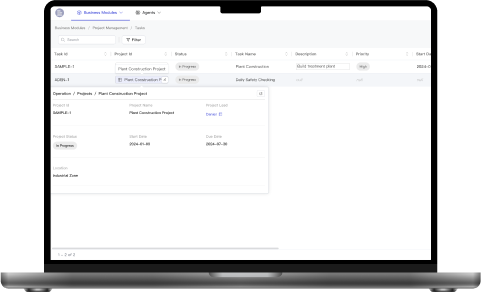

Bring your manufacturing ERP to life by connecting production data, asset health, and cost centers automatically. Aden links your shop-floor systems with financials, ensuring real-time visibility into output, performance, and expenses.

Monitor Equipment Uptime & Production KPIs

Track machine performance, downtime, and throughput with AI-powered production analytics. Aden automatically identifies deviations in cycle times, quality, and energy usage - giving operations leaders the insight to act before issues escalate.

Automate Resource & Material Tracking

Replace manual data entry with live sensors and digital logs. Aden tracks labor, material consumption, and equipment usage in real time - generating a full audit trail across lines, shifts, and plants.

Predict Maintenance & Prevent Downtime

Turn maintenance from reactive to predictive. Using AI maintenance planning, Aden detects early warning signs from equipment telemetry, scheduling service automatically to prevent unplanned outages and production delays.

Go Live

From line startup to full-scale production, Aden continuously optimizes your operations with real-time dashboards, automated cost allocation, and predictive insights - helping manufacturers improve throughput, reduce waste, and maximize profitability.

Match the right people, machines, and materials to the right production runs - based on capacity, availability, and profitability goals. Aden’s manufacturing ERP learns how your lines perform and automatically optimizes shift schedules and machine loads for peak output.

Capture production, maintenance, and labor data automatically - no spreadsheets or manual entry. Aden links factory operations software directly to your cost centers, giving you a live view of material usage, overhead, and efficiency across every line and plant.

Know which products, processes, or plants drive profit - before the quarter ends. Aden’s AI production analytics models detect waste, inefficiencies, and downtime patterns early, ensuring your team acts on data, not guesswork, to maximize throughput and margin.

From shop floor to boardroom, track up time, yield, and margin performance in one unified dashboard. Aden connects production, maintenance, and finance - providing real-time manufacturing visibility that keeps operations on time, on budget, and continuously improving.

Specialized AI modules that work autonomously yet operate as one intelligent system.

Be Part of the Next-Gen Workforce Transforming the Way We Work

Stop waiting months. Get your AI-native business platform running before your coffee gets cold.